Mastering Sheet Metal Design: The Power of a Flange Tool and Where to Find a Free Online Option

In the world of metal fabrication and design, precision and efficiency are non-negotiable. Sheet metal, with its versatility and strength, is a foundational material used across countless industries—from automotive and aerospace to electronics and home appliances. But to truly harness the potential of sheet metal, one must master the use of specialized tools. One such indispensable tool in the designer’s arsenal is the flange tool for sheet metal.

Whether you’re an engineer, product designer, or hobbyist working on a fabrication project, understanding how and when to use a flange tool can greatly streamline your workflow. Even better, with the rise of digital manufacturing tools, you can now access a free online flange tool, making professional-level sheet metal design more accessible than ever.

What is a Flange Tool for Sheet Metal?

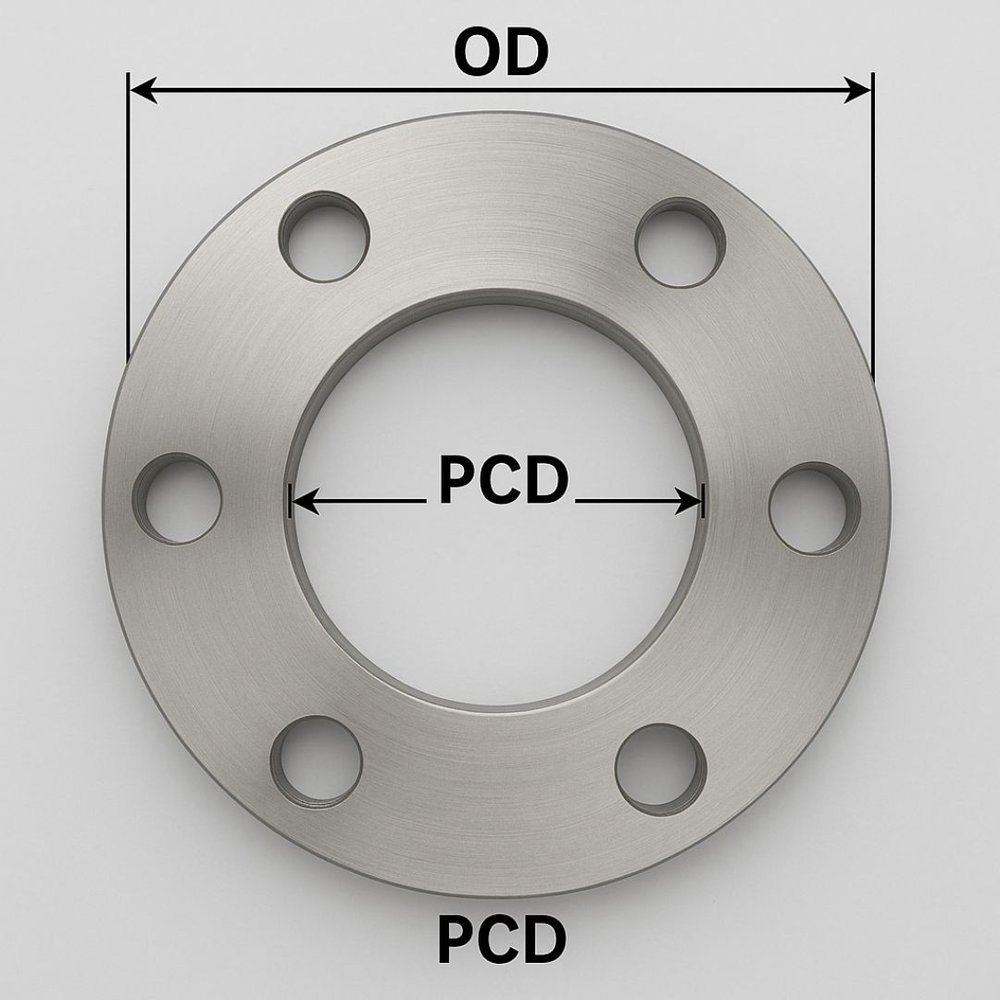

A flange is a protruding rim, edge, or lip used for strength, attachment, or alignment in sheet metal parts. When designing components, flanges play a crucial role in creating structural stability, facilitating assembly, and even improving aesthetics. A flange tool for sheet metal is a feature within CAD (Computer-Aided Design) software or a physical tool used in fabrication shops to easily create and manipulate these edges.

In CAD environments, the flange tool allows designers to quickly add flanges to a base sheet metal part, automatically adjusting parameters like length, angle, and bend radius. This saves hours of manual calculation and significantly reduces design errors, especially in complex assemblies where precision is paramount.

Why Flanges Matter in Sheet Metal Design

Adding flanges to sheet metal parts is not just a matter of aesthetics—it’s an engineering necessity. Here are a few reasons why flanges are essential in sheet metal design:

-

Structural Integrity: Flanges reinforce the strength of a part by adding material at critical edges.

-

Ease of Assembly: Flanges make it easier to connect multiple components, especially in riveted or screwed assemblies.

-

Design Flexibility: With flanges, you can achieve a wider variety of shapes and forms, enabling more innovative designs.

-

Reduction in Welding Needs: Proper flange design can minimize the need for welding, reducing labor time and cost.

Introducing the Free Online Flange Tool

Traditionally, sheet metal design tools were expensive and reserved for large-scale manufacturers. However, today’s designers have a powerful advantage: the free online flange tool. These cloud-based tools allow anyone with an internet connection to access professional-grade flange design features without the need for costly software licenses.

Here are a few benefits of using a free online flange tool:

-

Accessibility: No downloads, installations, or updates—just open your browser and start designing.

-

User-Friendly Interface: Most online tools are designed with simplicity in mind, ideal for both beginners and seasoned engineers.

-

Rapid Prototyping: Quickly test different flange configurations and export the model for laser cutting or CNC manufacturing.

-

Cost Savings: Eliminating the need for traditional CAD software subscriptions can result in significant cost savings, especially for small businesses and independent designers.

One example of a robust online flange tool can be found within platforms like Autodesk Fusion 360 (free for students and hobbyists) or SheetMetal.Me, which offers calculators and flange tools that don’t require a full software suite.

How to Use a Flange Tool for Sheet Metal (Step-by-Step)

Whether you’re using a desktop CAD program or a free online flange tool, the general process of adding a flange is fairly consistent:

-

Create the Base Sheet: Start with a flat sheet metal component. Define its dimensions and thickness.

-

Select the Flange Tool: Choose the flange option in your design tool—usually found under the sheet metal features tab.

-

Specify Parameters: Input flange length, angle (usually 90° by default), bend radius, and relief type (like rectangular or tear relief).

-

Position the Flange: Select the edge where the flange will be added. Most tools allow real-time preview and adjustment.

-

Finalize the Design: Once the flange is in place, review the part for manufacturability. Use built-in simulation or flat pattern tools to verify the design.

-

Export the File: Save your design in a compatible format (e.g., DXF or STEP) for laser cutting, punching, or CNC machining.

Final Thoughts

Incorporating flanges into your sheet metal designs is more than just a technical step—it’s a strategic choice that impacts the durability, functionality, and manufacturability of your products. Thanks to modern technology, powerful tools like the flange tool for sheet metal are no longer confined to large-scale manufacturing operations. Today, anyone can access a free online flange tool and design like a pro.

Whether you’re building a custom PC case, prototyping an industrial bracket, or creating artistic metalwork, embracing these tools will elevate your craftsmanship and unlock new creative possibilities. So, why wait? Explore a free online flange tool today and take your sheet metal designs to the next level.

- Share

YOU MIGHT ALSO ENJOY

Top Qualities to Look for in a World-Class SS Manufacturer

Stephen Romero - February 27, 2026

Smart Steel Choices for Long-Lasting Industrial Performance

Stephen Romero - February 26, 2026

Stainless Steel vs. Aluminum: Which is Better for Your Next Project?

Stephen Romero - February 26, 2026

search

FAST ACCESS

- art&gallery (4)

- Automotive (25)

- beauty (7)

- blog (535)

- Business (893)

- cleening (13)

- clinic (1)

- courier services (4)

- dentel care (6)

- Driving school (3)

- electronics (1)

- events (1)

- food (1)

- forests (11)

- gameing (5)

- Health (30)

- Health & Fitness (218)

- Home & Garden (16)

- Landscaping (1)

- Law (16)

- Lifestyle (15)

- machinery (5)

- Real Estate (9)

- Share Market (15)

- Shopping (7)

- Technology (31)

- tool (2)

- toys (2)

- Travel (43)

- Wedding & Events (344)

must read

Elevate Your Workout Wardrobe with Compression Gym Tops Women and Women Oversized Gym T Shirt

Stephen Romero - March 3, 2026

The Beauty of a Ceramic night light and Lithophane night light in Modern Home Décor

Stephen Romero - March 3, 2026

Reliable Commercial Cleaning Services in Calgary: Elevating Workplace Standards

Stephen Romero - March 3, 2026

Transforming Spaces with Greenhouse Conservatory Design and Botanical Glass Houses

Stephen Romero - March 3, 2026

recent post

ARCHIVES

- March 2026 (21)

- February 2026 (179)

- January 2026 (210)

- December 2025 (151)

- November 2025 (132)

- October 2025 (105)

- September 2025 (166)

- August 2025 (164)

- July 2025 (150)

- June 2025 (173)

- May 2025 (99)

- April 2025 (1)

- March 2025 (8)

- February 2025 (9)

- January 2025 (8)

- December 2024 (25)

- November 2024 (40)

- October 2024 (11)

- September 2024 (1)

- July 2024 (10)

- June 2024 (11)

- May 2024 (31)

- April 2024 (15)

- March 2024 (19)

- February 2024 (6)

- January 2024 (7)

- December 2023 (11)

- November 2023 (1)

- July 2023 (13)

- June 2023 (21)

- May 2023 (27)

- April 2023 (23)

- March 2023 (16)

- February 2023 (31)

- January 2023 (27)

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (11)

- August 2022 (14)

- July 2022 (13)

- June 2022 (19)

- May 2022 (17)

- April 2022 (10)

- March 2022 (12)

- February 2022 (8)

- January 2022 (9)

- December 2021 (19)

- November 2021 (4)

- October 2021 (6)

- September 2021 (4)

- August 2021 (4)

- July 2021 (10)

- June 2021 (6)

- May 2021 (2)

- April 2021 (2)

- March 2021 (45)

- August 2020 (31)

- July 2020 (30)

- June 2020 (29)